Some of the largest machines that keep the modern world running have a surprising device in common: the large bore shock absorber. These high-performance devices ensure that massive structures move smoothly, industrial machines operate with precision, and high-speed motion can be safely controlled in an emergency. Whether it’s a cable car gliding to a stop, a metal press shaping raw steel, or a drop tower delivering the ultimate thrill, ACE Controls’ large bore shock absorption technology makes it all possible. Here are six real-world applications where these shock absorbers make the crucial difference between precision and malfunction.

Paper Roll Machines: Sustainable Precision in High-Speed Operations

Paper roll machines operate at high speeds, handling massive rolls of paper that can weigh thousands of pounds. Without proper shock absorption, the force generated during stops, starts, and tension adjustments can wear down machinery, potentially leading to breakdowns and maintenance. ACE Controls’ CA Line Heavy Industrial Shock Absorbers are designed specifically for these high-impact environments. These self-compensating shock absorbers automatically adjust to changing energy conditions, ensuring smooth deceleration without the need for manual adjustments. With an energy capacity ranging from 32,000 in-lbs to 160,000 in-lbs per cycle and the ability to handle loads up to 718,707 lbs, these absorbers prevent damage to machine components, extend equipment lifespan, and reduce the risk of operational failures. The hardened steel construction and damping ability provide durability and reliability, making them an essential component in industrial paper production. When it comes to stabilizing high-speed paper processing and preventing sudden mechanical shocks, ACE’s CA Line ensures that paper roll machines run efficiently and safely.

Drawbridges: Ensuring Smooth and Reliable Operation

Drawbridges are feats of modern engineering that must lift and lower massive sections of roadway with precision and control. While spanning busy shipping channels and historic waterways, these structures have to endure the immense mechanical stress of holding up heavy roadways with every operation. Without proper shock absorption, the movement of a drawbridge can create excessive strain on its motors, gears, and structural components, leading to premature wear or even failure. That’s why heavy-duty industrial shock absorbers play a crucial role in dampening impact forces and ensuring smooth, controlled motion. By absorbing the energy generated as the bridge opens and closes (which can range up to 100 tons), these shock absorbers help prevent sudden jolts, reduce mechanical stress, and extend the lifespan of critical components. This not only enhances safety for vehicles and pedestrians but also minimizes costly maintenance and downtime. Thanks to precision engineering, modern drawbridges can operate reliably for decades, seamlessly balancing massive forces while keeping traffic and waterways moving.

Cranes: Managing Massive Loads with Precision and Safety

Cranes are the most essential part of a construction site dealing with enormous loads. By hoisting steel beams high above a worksite and maneuvering cargo containers onto ships, cranes must operate with absolute precision and control. A sudden stop or uncontrolled movement can create dangerous shock loads, threatening both the crane’s structural integrity and the safety of the site workers. That’s where ACE Controls’ large bore safety shock absorbers come in. Designed specifically for emergency stops, these shock absorbers help dissipate energy, reduce impact forces, and prevent mechanical damage when a crane reaches the limits of its acceleration. The large bore shock absorbers provide long stroke lengths and low reaction forces, allowing cranes to operate more smoothly and safely, even when handling extreme loads. Without these critical safety components, those abrupt starts and stops could cause equipment failure, load instability, or even catastrophic accidents. Whether used in the towering gantry cranes or high-speed industrial hoists, ACE Controls’ large bore shock absorbers are behind-the-scenes helping cranes run more efficiently, quieter, safer and more sustainable.

Cable Cars: Ensuring a Safe and Comfortable Ride

Cable cars provide breathtaking views and an efficient way to traverse steep terrain, but their operation involves complex mechanics and precise motion control. These systems must handle heavy loads, steep inclines, and frequent stops, all while ensuring a smooth and safe experience for passengers. A sudden jolt or uncontrolled deceleration could create discomfort for riders and place excessive stress on the cables and support structures. That’s where heavy-duty shock absorbers come into play. Installed in key areas of the system, they help dampen vibrations, control deceleration, and prevent sudden impacts when the cable car reaches a station or emergency stop. Self-compensating shock absorbers automatically adjust to changing loads, ensuring consistent and reliable performance regardless of passenger weight or environmental conditions. By absorbing the immense forces generated by these high-altitude transport systems, shock absorbers contribute to both passenger comfort and long-term infrastructure durability, making cable car travel not just scenic, but also smooth and secure.

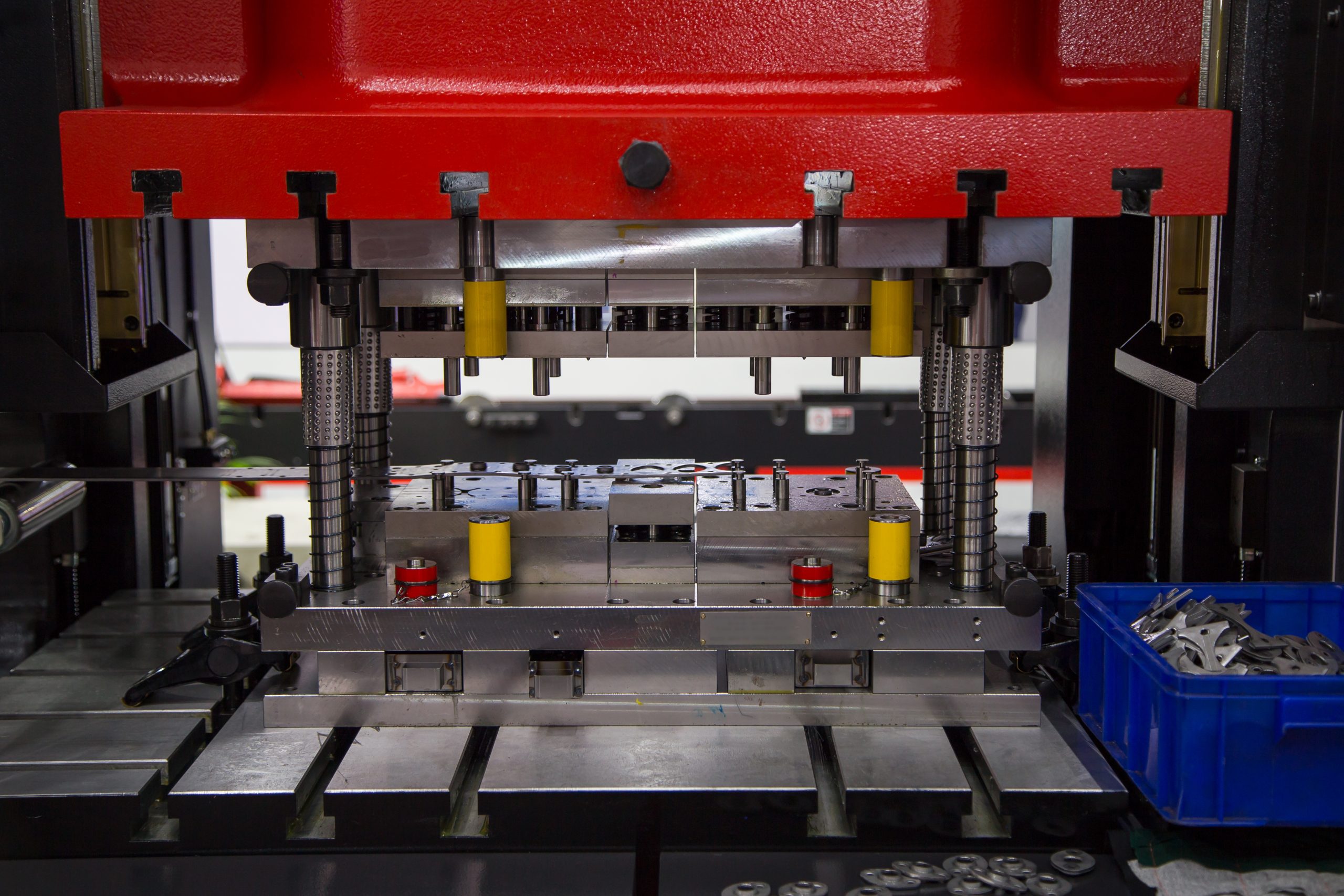

Metal Forming: Precision and Protection in the Most Dangerous Manufacturing

Metal forming is one of the most demanding processes in manufacturing, where immense forces shape, cut, and mold metal into precise components. These machines apply massive power, sometimes delivering thousands of tons of pressure in milliseconds. Without proper energy absorption, the repeated high-speed impact can cause excessive wear on machine components, misalignment, or even catastrophic equipment failure. Safety shock absorbers play a crucial role in protecting metal forming machinery by reducing impact forces, stabilizing high-speed motion, and preventing mechanical overloads. Designed for emergency stop applications, these long-stroke absorbers dissipate energy over an extended range, minimizing stress on both the press and the tooling. This ensures that each cycle runs smoothly, extends machine lifespan, and maintains the precision required for high-quality metal components. In a production environment where reliability and safety are paramount, shock absorbers are the hidden safeguard that keeps metal forming equipment running efficiently while reducing downtime and costly repairs.

Drop Towers: Delivering the Ultimate Thrill, Safely

Few amusement park rides deliver the same adrenaline rush as a drop tower—a thrilling experience where you’re hoisted high into the sky before plummeting back toward the ground at breathtaking speeds. While the sensation of freefall is exhilarating, the engineering behind the ride ensures a completely safe and smooth landing. Safety shock absorbers are a critical component of drop tower rides, absorbing the immense energy generated as the ride vehicle rapidly descends and comes to a controlled stop. Without them, the sheer force of the drop could cause structural damage to the ride or create uncomfortable jolts for passengers. Long-stroke safety shock absorbers help gradually dissipate impact forces, ensuring a smooth deceleration that keeps the experience thrilling yet safe. By using precisely engineered damping characteristics, these shock absorbers allow for repeated high-impact cycles, making them an essential part of delivering excitement while prioritizing passenger safety. No matter if you’re screaming in excitement or gripping your seat in anticipation, shock absorbers work behind the scenes to make every drop tower ride both exhilarating and secure.