Properly sizing your gas spring depends on the right data—from ambient temperature to mounting orientation. Identifying these parameters upfront will ensure you get the most out of your gas spring in terms of safety, reliability and operating life. And while it might seem like a lot to keep track of, ACE engineers can provide you with the tools, accessories and engineering support you need to get started.

Let’s take a closer look at some of the sizing parameters:

Hand force, or the amount of force required to move your load or hood. Our application engineers can help you determine the necessary hand force for different angles of movement.

Extension force. Gas springs use forces to counterbalance the weight of the moving load. Specifically, the amount of nitrogen inside the spring pushes the piston head—providing the necessary extension force.

Center of gravity (CoG). Understanding how gravity affects the geometry and weight of your load is critical when determining where to mount your gas spring, how much force you need to counterbalance the load—and where to reach that perfect balance. Flat lids with a uniform material have a CoG smack-dab in the center, whereas curved/angular hoods or hoods with multiple materials and densities can affect the CoG location. In these instances, the CoG is typically found using CAD.

Stroke length, or the distance the load must move. Consult your datasheet to learn how different forces will interact with the stroke, as well as how much force specific stroke lengths can handle.

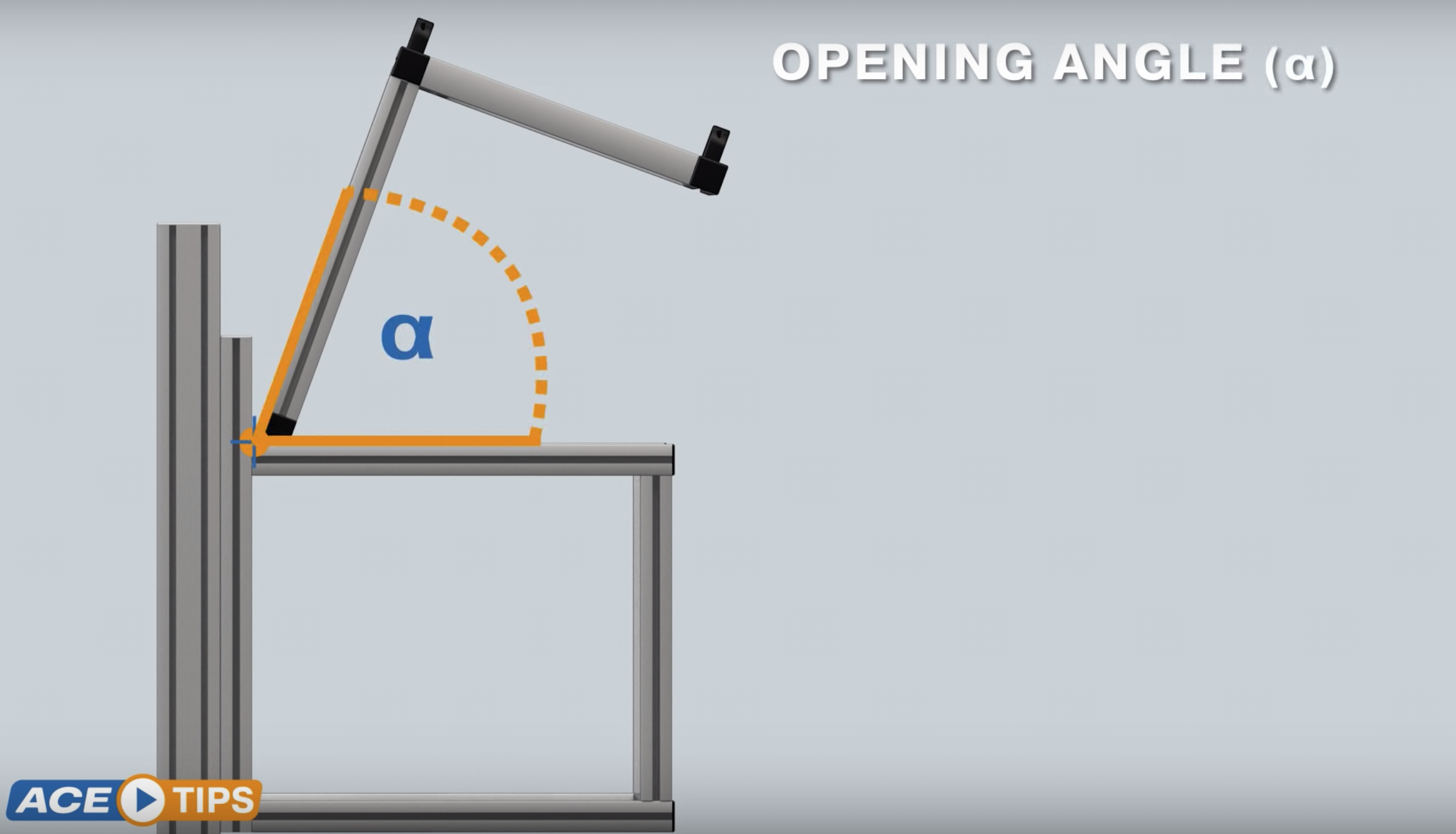

Mounting. How you mount your gas spring will determine both the opening angle and stroke. Linear applications, for example, have a straight stroke. Be sure to account for any nearby equipment or other obstructions that could affect the mounting location.

Materials. Since most gas springs are used indoors, they’re usually made from carbon steel. But depending on the application—saltwater environments or food and medical applications, for example—your gas spring may require rust-inhibiting or UV-coated materials.

And more. It’s important to know a variety of other parameters, including the ambient temperature, dimensions and weight of the load, pivot point (top, middle or bottom) and starting and finishing angles.

To make things easier for you, we cover these parameters in our online calculation tool, which uses 3D simulation to help you size your gas spring in just a few steps. Based on your specifications, we’ll create an application report with all the technical information you need—mounting points included. Just drill four holes, and we do the rest.

Visit our calculation page to get started.